Powder Topics

5.Ferrite Potential(Pertectic grade)

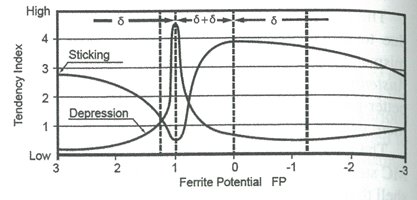

Casting of peritectic steel is a major issue in continuous casting. The ferrite potential will be explained before the mild cooling by using mold powder, which is important for casting of peritectic steel.

In general, peritectic steel refers to 0.10 to 0.16% C steel in the Fe-C binary system. However, since general steel is multidimensional, it is not necessarily in these carbon concentration ranges.

Wolf (quoted from M. Wolf and Kurz: Met Trans. Vol.12B 85 (1981)) introduced the term "ferrite potential" as a measure of the amount of peritectic reaction occurring in steel. Ferrite potential is affected by carbon content, but is also affected by other alloying elements. Some of these elements stabilize ferrite (Cr, W, Mo, Al, Si) and others stabilize austenite (Ni, Mn, Co, N, Cu). For low alloy steels, the ferrite potential (FP) can be calculated by Equation 1. Where, CP is the carbon potential defined in Equation 2.

Low alloy

CP=(wt%C)+0.04(%Mn)+0.1(%Ni)+0.7(%N)-0.14(%Si)-0.04(%Cr)- 0.1(%Mo)-0.24(%Ti)・・・・・(2)

|

|---|

| Refer from M.Wolf and Kurz : Met Trans.Vol.12B 85 (1981) |

It can be seen from this figure, peritectic steel is prone to cracking and depression, but it is less likely to be generated sticker. The choice of powder is important.