<

Powder Topics

4.3 Melting rate controll

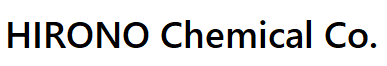

It can be seen that the melting

rate of powder changes depending on the specific heat, latent heat,

and thermal conductivity of the powder. In addition to these physical

property values, in the powder for continuous casting, the melting

rate is adjusted by adding carbon powder. The higher the amount of

carbon powder added, the slower the melting rate. In addition, the

smaller the particle size of the carbon powder, the greater the effect

of suppressing the melting rate. Carbon powder also has an

anti-sintering effect and a heat source, so while making a compromise

with those conditions, Adjust the type and amount of carbon powder.

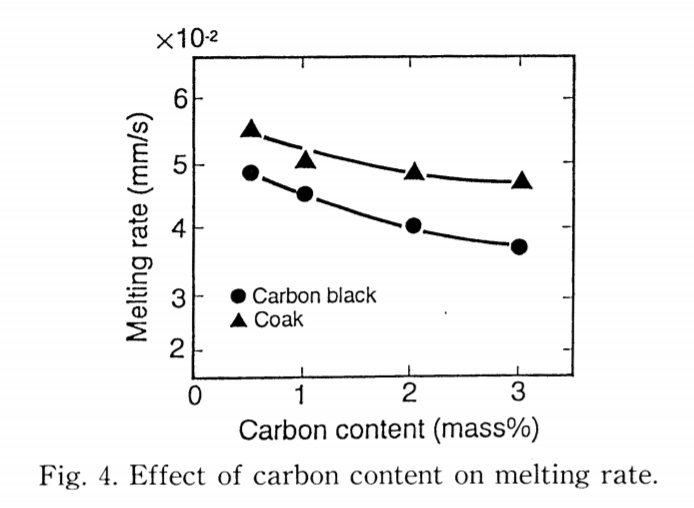

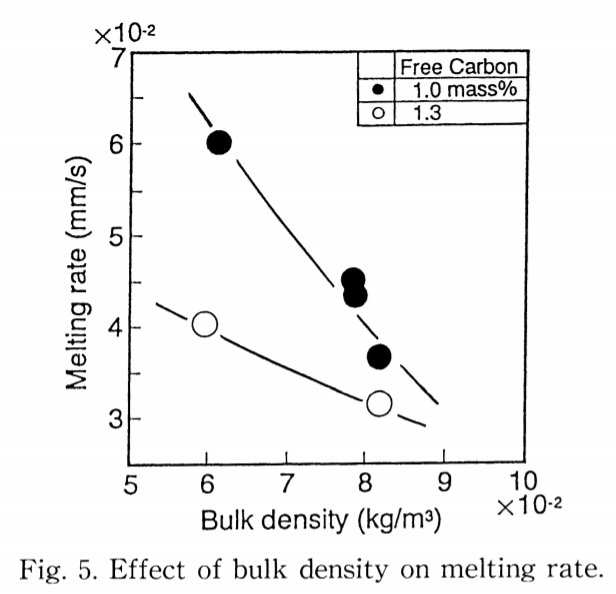

In addition, the melting rate changes depending on the components that

generate gas and the bulk density. For example, when carbonate is

added, the melting rate is increased by stirring with the

decomposition gas. Also, the higher the bulk density, the slower the

melting rate.

|

|---|

| after, Kawamoto et al. : Tetsu-to-Hagane VOL.80 NO.3 P.219‐224 1994 |

|

| after, Kawamoto et al. : Tetsu-to-Hagane VOL.80 NO.3 P.219‐224 1994 |

|

| after, Kawamoto et al. : Tetsu-to-Hagane VOL.80 NO.3 P.219‐224 1994 |