Mold Powder Topics

3.Construction of continuous casting powder

Continuous casting flux is a

mixture of oxides whose main component is CaO-SiO2, with

fluoride and carbon added. In the CaO-SiO2 system, the

mass% is 1:1, that is, CaO/SiO2 (basicity) 1, and the

melting point is

will be the lowest. However, considering the casting temperature of

steel, the melting point of CaO-SiO2 alone cannot be said

to be sufficiently low. Therefore, add oxides such as Na2O

and fluorides such as CaF2 to obtain an appropriate

viscosity and melting point.

adjust. Also, carbon powder is added to adjust the melting rate. A

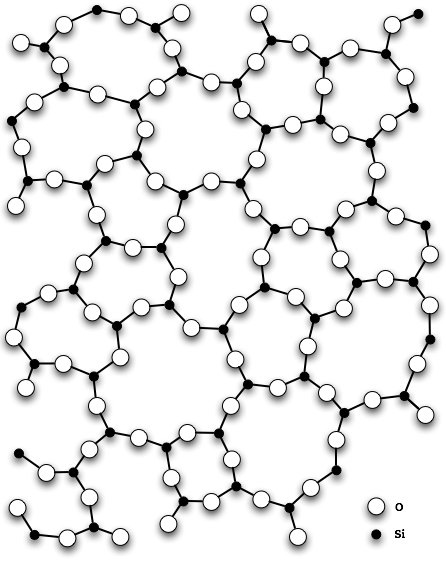

melt containing SiO2 generally has a network structure of

SiO2. Since the network structure of SiO2 is a

large fluid unit, it has a higher viscosity than monoatomic melts such

as metals.

The network structure of SiO2 is divided by the addition of basic

oxides and fluorides, and the flow unit becomes smaller, so the

viscosity decreases.

|

|

|---|---|

| Phase diagram of CaO-SiO2 | Structure of SiO2 |

| after, http://www.engineering-eye.com/THERMOCALC/details/case/13.html |

after, https://ja.m.wikipedia.org/wiki/%E3%83%95%E3%82%A1%E3%82%A4%E3%83%AB:SiO2_-_Glas_-_2D.png |